Modifying the spectral performance of cover materials in greenhouses can provide significant energy savings and improve plant productivity.

To test this hypothesis, the just-completed ‘Smart Glass film impacts on energy use and productivity in greenhouse lettuce’ (‘Smart Glass’) project monitored the performance of two innovative low-cost cover materials – energy-saving ‘ultra-low reflectivity’ Smart Glass (SG ULR-80), developed for architectural use, and Luminescent Light-emitting Agricultural Film 620 (LLEAF-Red) – on plant growth, photosynthesis, yield and quality in greenhouse-grown lettuce crops.

The project team found that plant growth, photosynthesis, yield and quality all varied in response to each of the prototype cover materials, with impacts varying according to cultivar and growth season.

Lettuces grown under SG ULR-80 showed significantly lower rates of photosynthetically active radiation (PAR), especially under high light conditions. Two of the three lettuce cultivars grown under SG in summer also weighed 10-15 per cent less than equivalent control crops; however, SG also reduced summer energy costs by deflecting heat.

Covering trial crops in LLEAF-Red did not affect the fresh weight of resulting lettuces appreciably in early autumn but later in the season, under lower light conditions, it resulted in heavier lettuces than those produced under either SG ULR-80 or hazed greenhouse glass (the control), with the significance of the difference varying according to cultivar.

The project team concluded that with some modifications, both prototype film could become viable, cost-effective solutions for commercial growers looking to improve greenhouse energy efficiency and crop yield.

‘Potential energy-saving SG reduced [crop yield] but LLEAF increased the yield,’ the final project report states. ‘The energy-saving ability of SG could be combined with yield-increasing potential of LLEAF.’

A follow-up CRC project is in the pipeline.

Aerial view of the experimental glasshouse at the National Vegetable Protected Cropping Centre on WSU’s Hawkesbury campus, showing the LLEAF-Red, (right) and Smart Glass ULR-80 (bluish, left) films retrofitted above adjacent trial lettuce bays. Credit: Kayla Le Gros

Unpacking the research

The prototype films

Previous trials of Smart Glass ULR-80 showed that it blocks much of the solar radiation that contributes to heat gain while transmitting most wavelengths required by plants for photosynthesis and growth. However, SG also reduces light intensity in some important wavelengths; hence it can adversely affect plant growth and development, photosynthesis, biomass partitioning, yield and quality.

In an earlier project with industry body Hort Innovation, WSU scientists found that deploying Smart Glass ULR-80 with glasshouse-grown eggplant and capsicum crops increased energy- and resource-use efficiency with minimal negative impact on fruit quality; however, its use resulted in significant reductions in photosynthesis, and in eggplant (but not capsicum planted in low light season) yield. The researchers concluded that SG ULR-80 should be re-engineered to increase penetration of ultraviolet (UV) and PAR but continue to block the long-wave radiation that contributes to heat gain. The researchers also recommended testing SG ULR-80 on non-fruiting crops such as leafy greens – hence this project.

LLEAF Pty Ltd’s patented luminescent light-emitting agricultural films (LLEAF) have been shown in previous trials to deliver significant increases in crop production and in energy and water-use efficiency. LLEAF 620 (LLEAF-Red) works by shifting sunlight into a spectrum more beneficial to plant growth. Crop trials with LLEAF show potential to increase yield and improve plant cycle and harvest control.

Luminescent Light-Emitting Agricultural Film (LLEAF)-Red (pink) and SG ULR-80 (blue) installed above a trial lettuce plot in the high-tech, controlled-environment glasshouse on Western Sydney University’s Hawkesbury campus. Credit: LLEAF Pty Ltd

The research

The two prototype films were installed over trial bays growing leafy green and climbing-vine crops within the high-tech controlled-environment glasshouse at Western Sydney University’s Hawkesbury Institute for the Environment (HIE).

Six adjacent bays – two retrofitted with SG ULR-80, two with LLEAF-Red, and two ‘control bays’ fitted with hazed greenhouse glass – were used to grow a trio of elite lettuce cultivars supplied by seed distributor Rijk Zwaan..

Trials were conducted under several different light conditions (summer, early and late autumn) to understand the impact of seasonal light variation under SG and LLEAF on plant growth and productivity.

Growth environment, fertigation use, crop morphology, colour, photosynthesis, yield and quality parameters were measured during all three seasonal lettuce trials. Crop nitrogen status was monitored, and leaf samples were taken.

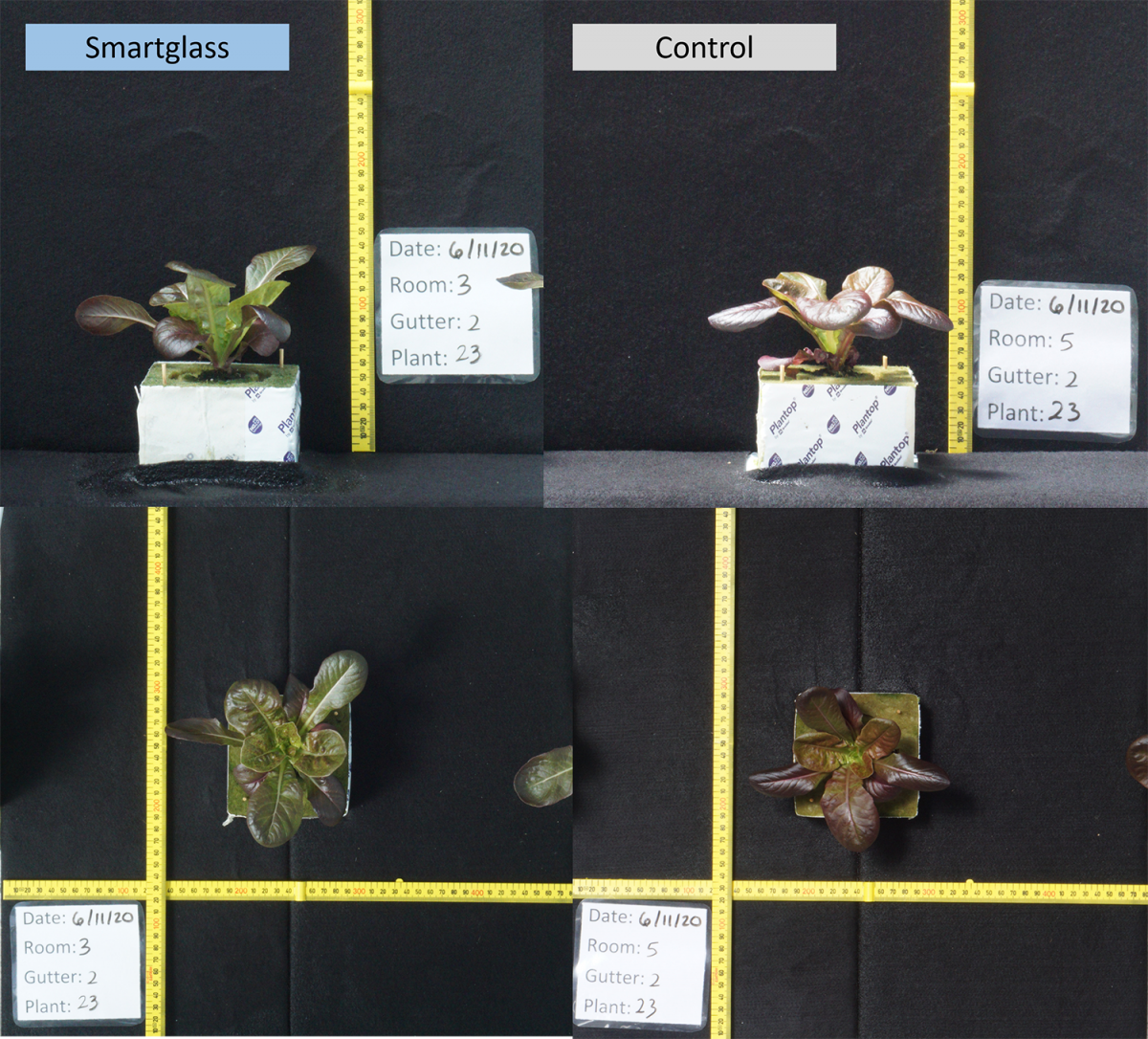

Samples of red cos lettuce grown under SG ULR-80 and LLEAF-Red in varying seasonal light conditions. Credit: Western Sydney University

Key findings

Plant growth, photosynthesis, yield and quality all varied in response to SG-ULR-80 and LLEAF-Red, with impacts varying according to the cultivar and growth season.

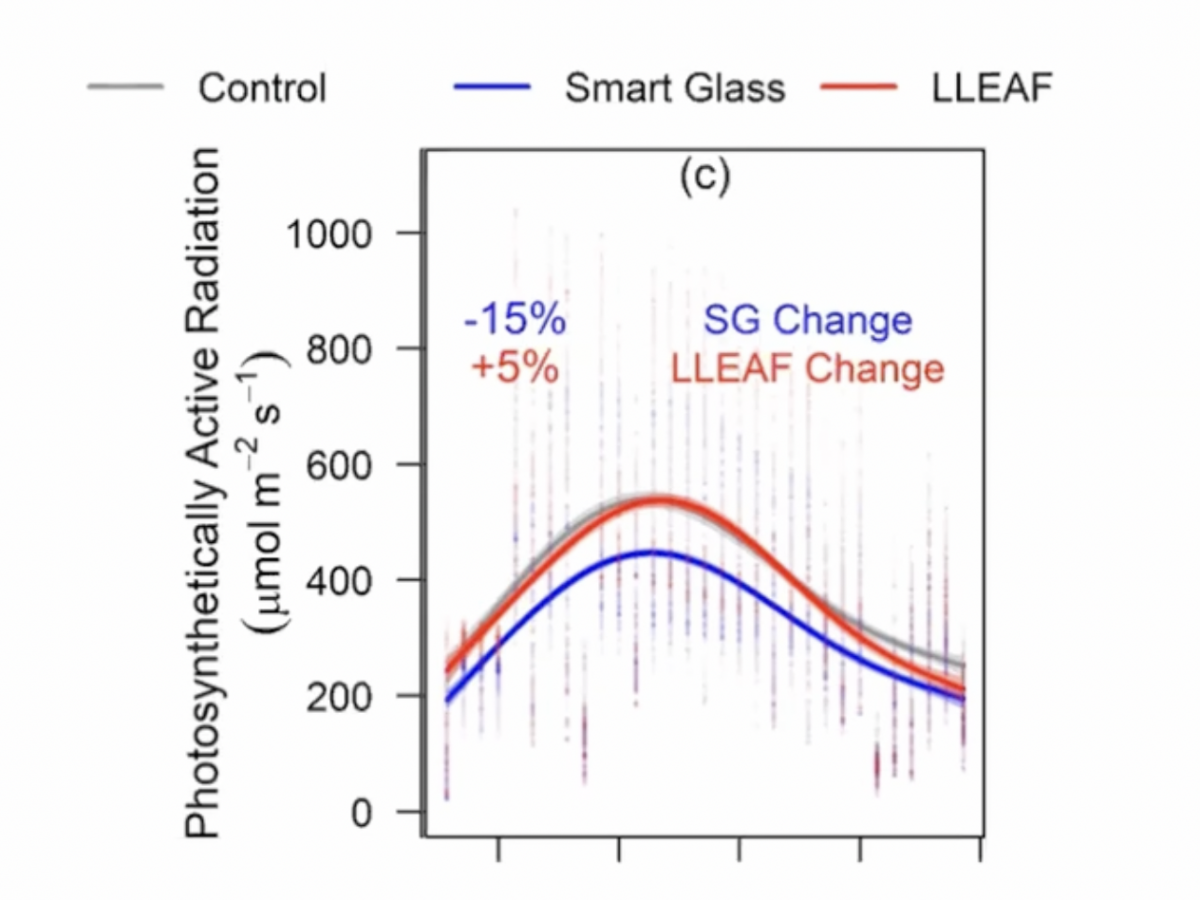

1. Lettuces grown under SG ULR-80 had significantly lower rates of photosynthetically active radiation (PAR), especially in summer

“Preliminary results showed that the SG reduced photosynthetically active radiation (PAR) more during the high light conditions of summer (-19%) relative to the low light conditions of late autumn (-15%),” WSU researcher and project team member Dr Sachin Chavan explains. “LLEAF-Red shifted green light wavelengths to red but did not significantly impact the light intensity (PAR).”

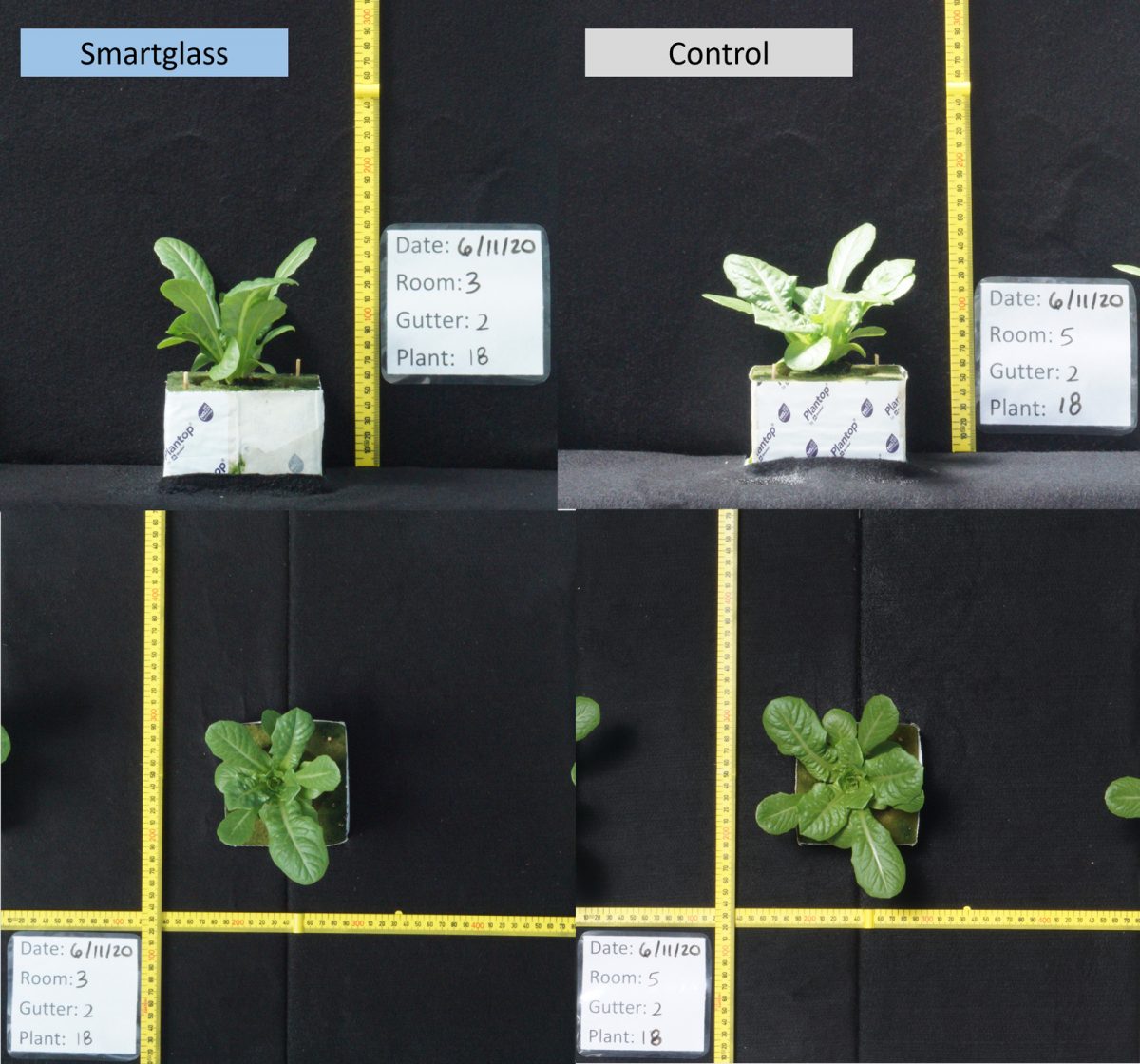

Samples of green cos lettuce grown under various conditions in the HIE glasshouse. Credit: Western Sydney University

2. Growing under SG ULR-80 impacted lettuce colour

“Only SG significantly affected colour parameters in all cultivars,” Dr Chavan says. Vegetation was generally more reddish in lettuces grown under SG ULR-80, while LLEAF-Red did not appear to affect vegetation colour.

3. SG reduced fresh weight in summer-grown butterhead and green cos cultivars

Over summer, covering the crop with SG ULR-80 reduced fresh weight in both butterhead and green cos cultivars by 10 to 15%, but SG covering had little impact on their weight in late autumn, Dr Chavan says.

Results of lettuce grown under Smart Glass ULR-80 and controlled glass. Credit: Western Sydney University ‘Smart glass’ project team

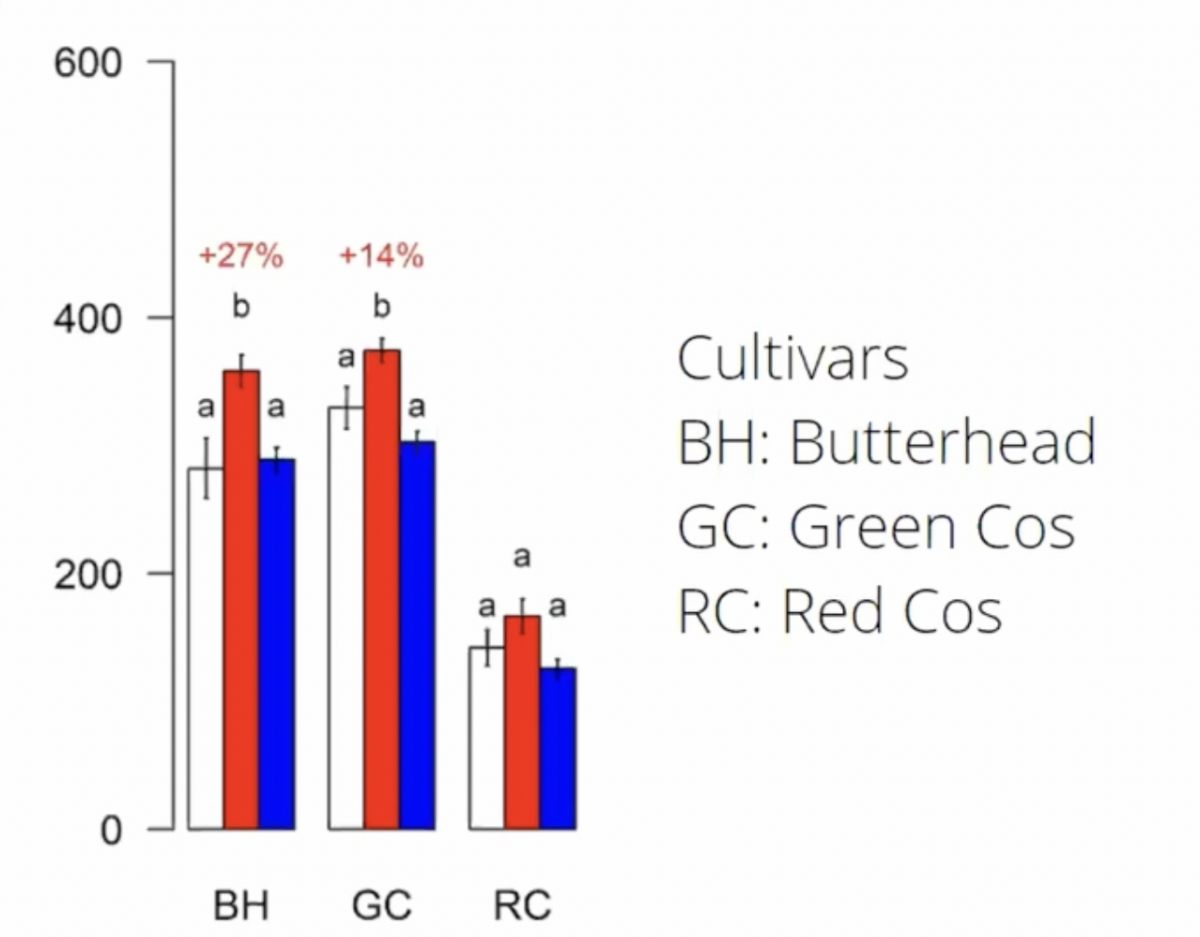

4. LLEAF-Red increased fresh weight significantly in late-autumn butterhead and green cos

Covering trial crops in LLEAF-Red did not affect fresh lettuce weight much in early autumn but under the lower light conditions of late autumn, it resulted in heavier lettuces than those produced under either SG ULR-80 or the control crop under hazed greenhouse glass.

The significance of the difference varied according to cultivar. Fresh weight of both butterhead and green cos lettuces grown under LLEAF-Red in late autumn was significantly higher than that of the same cultivars grown under under conventional greenhouse glass or SG ULR-80.

“LLEAF-Red did not affect the plant fresh weight during high light conditions of early autumn, but increased plant fresh in weight by [a significant] 27% in the butterhead lettuce and by 14% in green cos lettuce during late autumn,” Dr Chavan explains.

The fresh weight of red cos grown under LLEAF-Red in the same season, while not significantly greater than the red cos controls, also tended in that direction.

“Red cos plant fresh weight did not show significant changes in response to either SG ULR-80 or LLEAF-Red, but there was an increasing trend for LLEAF-Red,” Dr Chavin notes.

Results of lettuce grown under Smart Glass ULR-80 and controlled glass. Credit: Western Sydney University ‘Smart glass’ project team

“In summary, [being grown under] SG ULR-80 reduced plant fresh weight in lettuce cultivars only in the high light conditions of summer and early autumn, [while being grown under] LLEAF-Red increased plant fresh weight only during the low light conditions of winter,” Dr Chavan says.

Project lead Dist. Professor David Tissue, inspecting trial lettuce crops with Glasshouse technician and Masters student Chelsea Maier and postdoc Sachin Chavan. Credit: Sally Tsoutas for Western Sydney University

Next steps

LLEAF-Red film proved more conducive to growth in greenhouse lettuce crops but, according to the project team, further testing and modification are needed before it will be viable for commercial horticulture.

‘LLEAF may be useful for lettuce growth, but more chemical and nutritional analyses are required to make that decision,’ the team’s final quarterly project report states. ‘LLEAF must also be tested in climbing vine crops (e.g., cucumber and capsicum) to assess general use in horticulture.’

Already, the project has spawned new trials of the prototype films with other greenhouse-grown crops.

WSU crop scientists have successfully completed two replicate trials of Lebanese and Continental cucumber under SG ULR-80 and LLEAF-Red. The latter trial encompassed detailed carbon assimilation measurements to investigate the impact of both prototype films on leaf photosynthesis and associated changes in metabolic pathways. Processing of stored samples for quality analysis is currently underway.

“In our next crop trial, in the 2022-2023 growing season, we plan to test SG ULR-80 and LLEAF-Red to grow two capsicum cultivars,” Dr Chavan says.

Trialling cucumber crops in the HIE glasshouse. The smart films have been trialled in leafy green vegetables and vine crops; next they will be tested on capsicum crops. Credit: Western Sydney University/HIE

A new prototype film for growers

The lettuce and cucumber trials at WSU showed that Smart Glass ULR-80 ‘will not be a viable option for growers, given the yield penalty due to reduction in useful light’, the project team stated in its final report – which also acknowledges that ‘this, potentially, could be offset by energy savings’.

Based on results from this project, a recently funded CRC project involving Hort Innovation will look to develop a new SG film, better suited to commercial indoor horticulture. Further research on LLEAF films will also be undertaken as part of the project – stay tuned for ‘LLEAF-Purple’.

“Ultimately, our objective is to reduce resource use – energy, water and nutrients – and increase crop productivity and quality in a sustainable protected-cropping environment,” project lead Distinguished Professor David Tissue says.

Costa Group’s vast Tomato Exchange glasshouse facility near Guyra, NSW. Once the prototype ‘smart films’ have been fine-tuned, they can be used by commercial growers such as Perfection Fresh and Costa Group to optimise the amount of useful light reaching crops grown under glass, simultaneously filtering out heat-producing radiation. Credit: Costa Group

Real-world impact

The findings of the just-completed ‘Smart Glass-’ project will inform the fine-tuning of both prototype films prior to commercial release and adoption.

Down the line, other CRC partners, such as industry leaders Perfection Fresh and Costa Group, will benefit from access to improved technology backed by robust performance data.

Lead image: Lettuce trials under smart glass in the experimental glasshouse at WSU’s Hawkesbury campus. Credit: Western Sydney University