As part of his doctoral research, contributing to the ‘IoT for indoor cropping’ and ‘Automated crop monitoring for PC industry’ projects, PhD student Namal Jayasuriya has developed and successfully tested a cost-effective hands-free way to estimate plant height in high-tech glasshouses.

“Protected horticulture requires highly skilled labour, and automation can play a role in addressing this skill shortage,” says Western Sydney University Professor Oula Ghannoum, ‘Automated crop monitoring’ project lead and one of Jayasuriya’s supervisors.

With height generally a reliable proxy for vegetative growth, and estimating plant height being a labour-intensive task, having a fast, inexpensive, hands-free way to ascertain this parameter – and, potentially, other important crop features – will benefit indoor crop producers, freeing up workers for other tasks and enabling growers to make informed crop-management decisions remotely.

In this research paper, explains lead author Jayasuriya, “we demonstrate machine vision and AI based plant height estimation for horticultural crops, targeting commercial scale automated crop monitoring, […] designing a simple and affordable imaging platform to measure vertically supported taller plants”.

Namal Jayasuriya, using his imaging platform to acquire image data for estimating plant height on trial capsicum crop in the NVPCC glasshouse at Western Sydney University’s Hawkesbury Institute for the Environment. Jayasuriya is the lead author on a paper recently published in prestigious academic journal Computers and Electronics in Agriculture, detailing his doctoral research. Credit: FFS

Overcoming obstacles to accurate image-based monitoring

Jayasuriya’s literature review showed that while imaging technology has been used before to ascertain plant height in field crops, few such studies have been conducted in advanced indoor production facilities.

“Commercial-scale automated crop monitoring in protected horticulture lags behind research-purpose plant phenotyping,” he explains. “Vertically supported tall crops in semi-controlled high-tech glasshouses are a special crop type, and image-based automated crop monitoring is rarely targeted in research literature.”

According to Prof. Ghannoum, “Starting from nothing and stepping into a multi-disciplinary research field which is new to everyone was a challenging journey.”

To develop a reliable automated image-based method for estimating plant height in a high-tech glasshouse setting, several challenges had to be to overcome. Key among them, says Jayasuriya, were:

- researching and designing a suitable imaging platform for compact crop infrastructure under ambient light;

- engineering and developing a low-cost image data-acquisition platform using only off the shelf materials, acquired with student funds;

- identifying plant tops over a number of problems, such as occlusion and varying light conditions; and

- 3D processing with ‘noisy’ depth images.

“Correction of erroneous depth data due to camera calibration error, identifying plant tops and bases on both 2D and 3D spaces, identifying unidentified plant tops in the middle of a frame using neighbour frames, distinguishing foreground plant tops from background plat tops, eliminating outlier plant bases, and estimating plant heights are the challenges that we addressed in this work,” state Jayasuriya et al. in the paper.

A trial capsicum crop, growing in the National Vegetable Protected Cropping Centre (NVPCC) on WSU’s Hawkesbury Campus. Jayasuriya’s experiments in plant-height estimation were conducted on capsicum plants within this state-of-the-art, semi-automated glasshouse facility. Credit: Western Sydney University

Key findings

The research team was able to develop and successfully trial a robust, low-cost imaging method that enabled them to remotely monitor the height of plants in a high-tech glasshouse facility with high degrees of accuracy and reliability. Key findings were as follows, says Jayasuriya.

- Low-cost RGBD cameras can be used for plant height estimation in protected facilities, and even more impressive results are seen when the crops are grown under ‘Smart Glass’ film.

- An image-data-acquisition setup, with a single camera affording a top-angled view, can be used to estimate the height of plants up to 2.5 metres tall in compact glasshouse setups.

- Machine learning and 3D processing can be used effectively and efficiently for robust plant top and base identification for plant height estimation.

“It is evident that the system we proposed is a cost-effective and viable solution for monitoring the growth of protected crops with Smart Glass film (𝑅2 = 0.96), LLEAF film (𝑅2 = 0.79), and diffuse light roofs (𝑅2 = 0.87),” Jayasuriya states in the paper’s Conclusion.

“This study has confirmed the accuracy of the system to measure the growth of plant lines for 80% of the growth cycle, with the Smart Glass film showing the best results [at] 90% of the growth cycle and the accuracy per plant level above the noise level.

“If a more advanced depth camera is used […] the accuracy and usability of the system could be further improved for any lighting situation.”

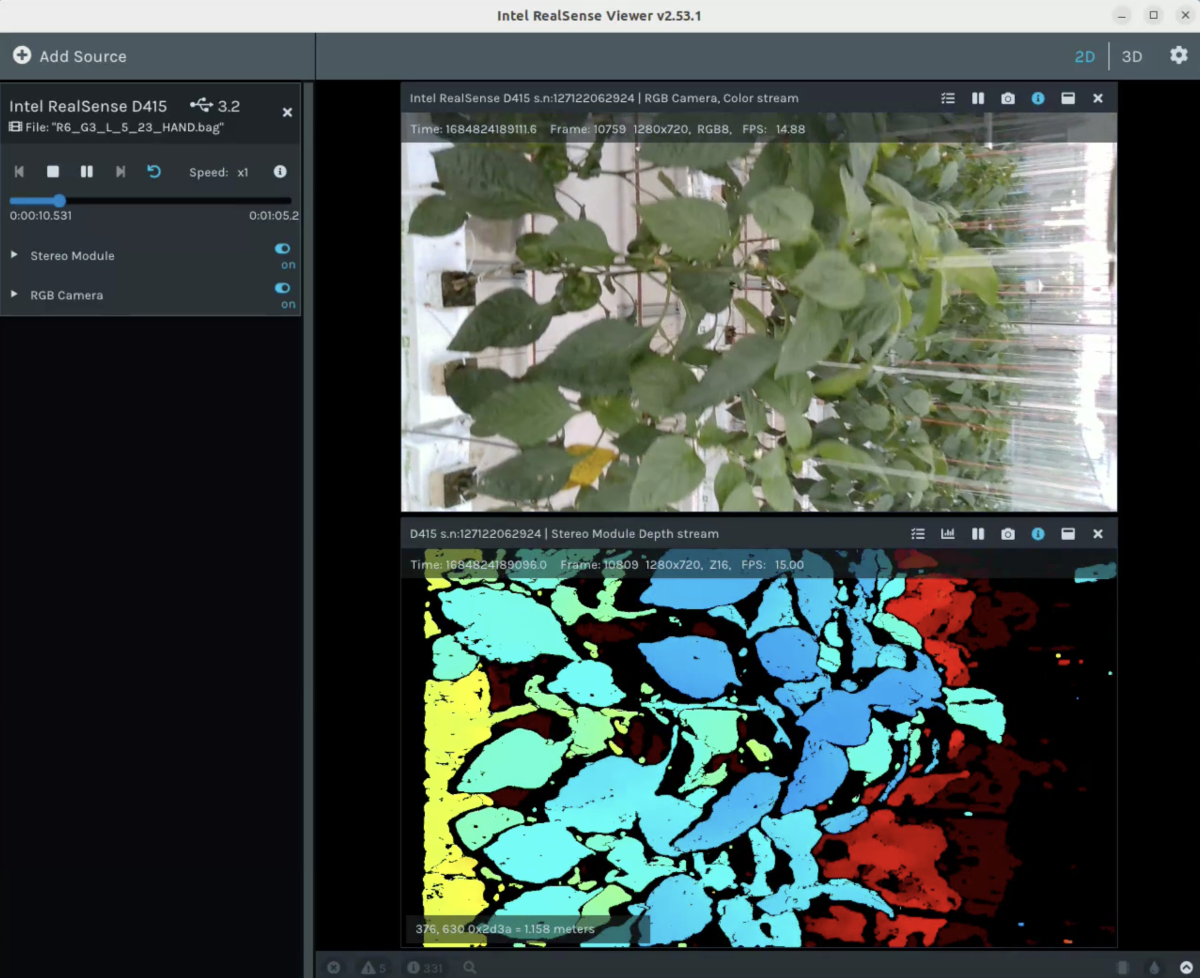

A screenshot of imaging data Jayasuriya obtained as part of his doctoral research developing a low-cost automated method for estimating plant height in high-tech indoor cropping facilities. Jayasuriya’s work is part of a broader collaborative initiative between protected cropping and data experts, industry partners and Future Food Systems to find cost-effective automated solutions that benefit Australia’s protected cropping sector and contribute to sustainable food production. Credit: Western Sydney University

A multi-disciplinary collaboration

The diversity of the team reflects the multi-disciplinary, collaborative nature of the research. It included experts in plant physiology, protected cropping, phenotyping, system engineering, robotics, IoT, sensor systems, big data, programming and automation, computer vision and machine learning, Jayasuriya says.

Jayasuriya’s own expertise lies in computer science and Internet of Things (machine-to-machine learning). His three co-authors on the paper, also his co-supervisors, span a range of academic disciplines. Western Sydney University Professor Oula Ghannoum‘s fields of expertise are plant physiology and horticulture; Associate Professor Yi Guo’s are data science and machine learning; while Professor Wen Hu, from UNSW Sydney’s School of Computer Science and Engineering, brings expertise in computer engineering and sensor technologies.

Jayasuriya’s cross-disciplinary skills and expertise were invaluable in furthering the collaboration, says Prof. Ghannoum, enabling him to make best use of the input he received from multiple industry and research partners.

“As the starting student of such a complicated project, Namal was able to deal with all the different disciplines, with his previous research expertise, technical skills, and, with the guidance of supervisors” she says. “Marking the first milestone, the team was able to publish ‘Machine vision-based plant height estimation for protected crop facilities’.

Jayasuriya tests the new imaging system on capsicum plants. Next steps are to trial the system using advanced camera technologies such as hyperspectral and Lidar, with a view to developing an advanced multi-camera system that can be used to monitor crop growth in commercial-scale glasshouses and vertical farms. Future research will target other proxies of growth and health, such as total leaf-area estimation, fruit quality and harvest estimation; and will trial the technology on different crops. Credit: FFS

Next steps

Next steps on the path to commercialisation for his automated crop-height estimation method, Jayasuriya says, are to use “advanced camera technologies such as hyperspectral and Lidar, and [develop] an advanced multi-camera system, targeting monitoring of commercial-scale glasshouse facilities and vertical farms”.

Future research, he says, will target “other proxies of growth and health, such as total leaf-area estimation, fruit quality and harvest estimation, crop-health monitoring and early disease identification”.

Professor Oula Ghannoum, a crop scientist at Western Sydney University, is one of Jayasuriya’s three supervisors, and part of a multi-disciplinary, collaborative research team that includes university and industry partners as well as Future Food Systems. Credit: Western Sydney University

The broader picture

Jayasuriya’s doctoral research project is contributing to the four-year ‘IoT for indoor cropping’ project, led by Prof. Hu and co-funded by industry partner WBS Technology and Future Food Systems, with in-kind support from Western Sydney University and UNSW Sydney. This project is supporting Namal’s PhD scholarship.

His work is also contributing to a major five-year collaboration led by Prof. Ghannoum and co-funded by Hort Innovation, industry partner Vertical Patch and Future Food Systems, with in-kind support from Western Sydney University. Over its lifespan, the ‘Automated Crop Monitoring for Protected Cropping’ project will involve several PhD students and postdoctoral researchers, and will entail developing new, low-cost remote-monitoring systems for glasshouses based on linked embedded sensor devices; robotic systems; and the required software systems.

Download the paper

Namal Jayasuriya, Yi Guo, Wen Hu and Oula Ghannoum, ‘Machine vision based plant height estimation for protected crop facilities.’ In Computers and Electronics in Agriculture, Feb 2024 issue. Download the pdf here.

Lead image: Namal Jayasuriya, a Western Sydney University PhD student backed by Future Food Systems and industry partner WBS Technology, with the low-cost automated imaging platform he has been developing as a way to ascertain plant height, and potentially, other parameters; in advanced protected cropping facilities. Credit: FFS