Challenge The conventional Maillard conjugation process, though effective for improving the functional and bioactive properties of biomolecules, is time-consuming and difficult to control. It often requires several weeks to complete and results in excessive browning due to the uncontrolled nature of the reaction. These factors significantly limit its scalability and applicability in industrial food processing. Furthermore, many existing methods rely on chemical solvents or additives, making them incompatible with the growing consumer demand for clean-label and sustainable food products. To be viable for commercial use, a new approach was needed – one that could reduce processing time, eliminate harsh chemicals, and produce functionally enhanced ingredients suitable for modern food systems.

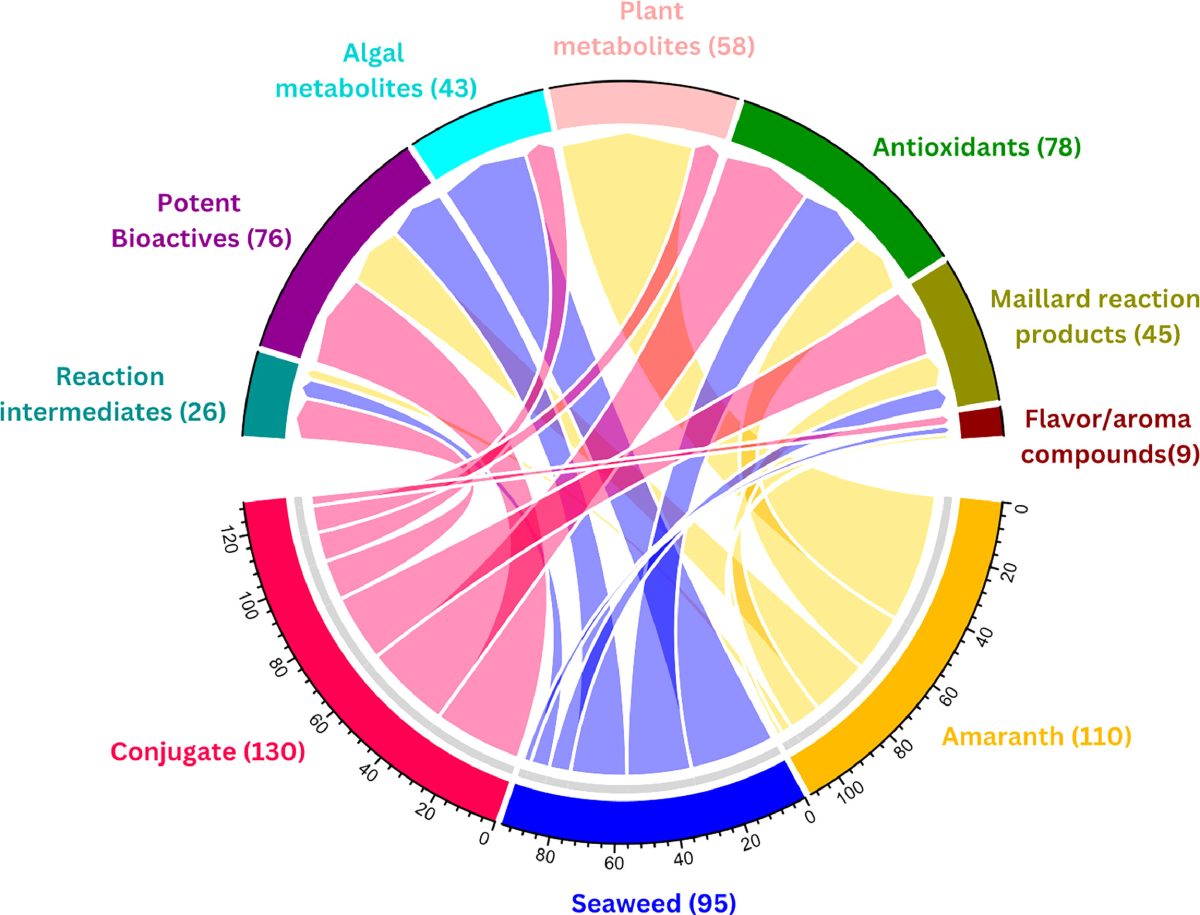

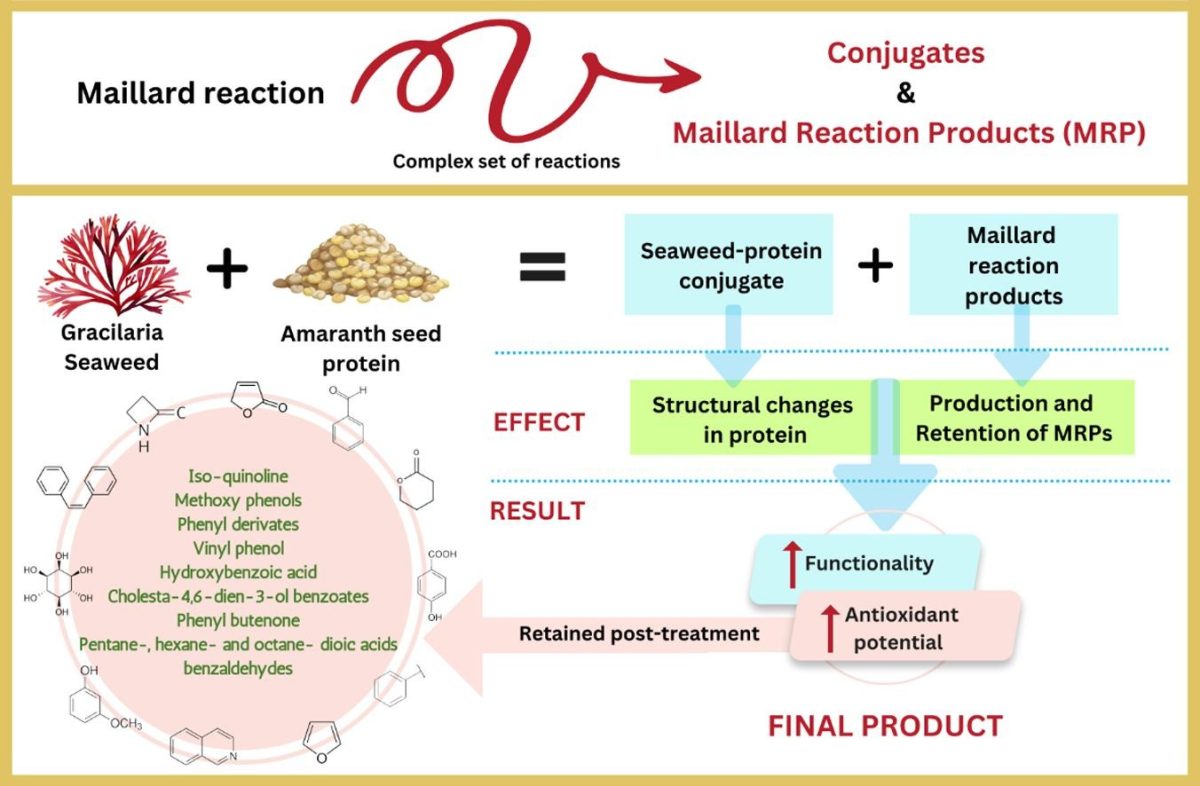

Solution This project introduced an innovative ultrasonic-assisted method to produce Maillard conjugates using non-traditional plant proteins, specifically amaranth, combined with polysaccharides extracted from locally sourced seaweed. Unlike conventional methods, this technique relies on ultrasonic energy to drive the conjugation reaction, eliminating the need for chemical solvents and drastically reducing the processing time. To streamline and optimise the process, an artificial neural network was developed and trained using existing experimental data. This model predicted the optimal parameters for conjugation, which were subsequently validated through laboratory trials. Once confirmed, the optimised process was used to produce Maillard conjugates that were then spray-dried, employing a scalable unit operation already widely used in the food and dairy industries. This not only ensured the feasibility of commercial production but also resulted in a clean, functional ingredient ready for use in nutraceutical and functional food formulations.

Impact The development of this ultrasonic-assisted conjugation method represents a significant step forward in the production of functional food ingredients. The resulting spray-dried conjugates demonstrated enhanced techno-functional properties, including improved solubility, emulsification, water and oil holding capacities, and antioxidant potential. Importantly, the process supports clean-label claims by avoiding chemical solvents and leveraging natural, under-utilised resources such as amaranth and seaweed. The use of spray-drying as the final processing step ensures compatibility with existing industrial equipment, facilitating rapid adoption by manufacturers. This work not only addresses current limitations in Maillard conjugation but also contributes to the broader goals of sustainability and innovation in food science, enabling the development of next-generation products with validated health and environmental benefits.