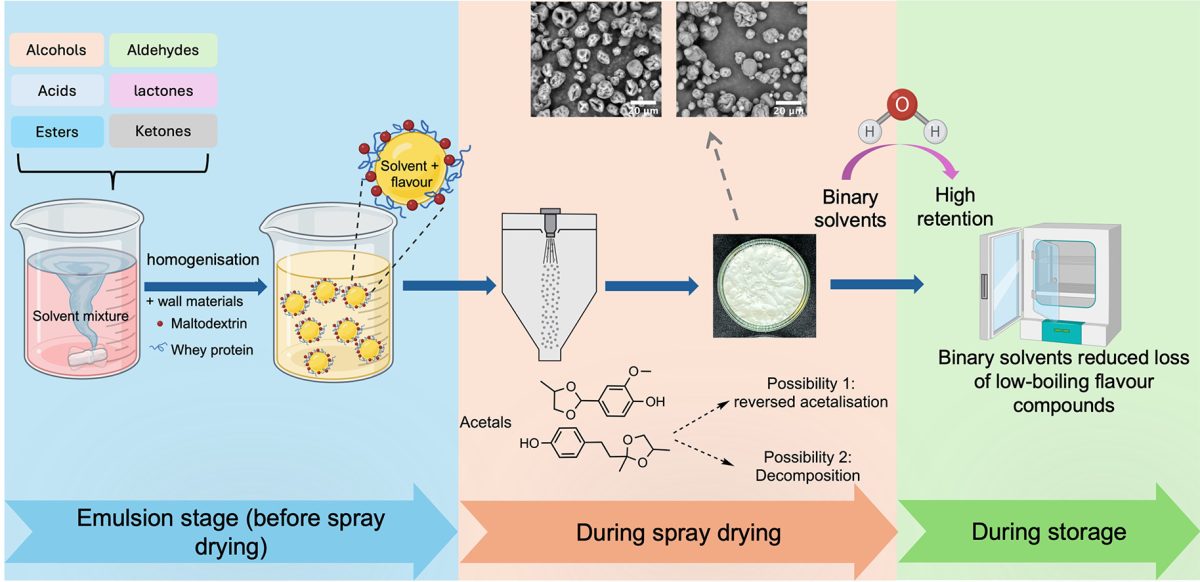

Challenge Baker & Co, an Australian-owned company based in Western Sydney, specialises in sourcing and developing natural ingredients for the food, beverage, cosmetic, fragrance, and pharmaceutical industries. While their in-house capabilities currently focus on liquid-based flavour production, the company relies on external partners for manufacturing other product forms. As part of a strategic expansion at their Huntingwood facility, Baker & Co aims to produce powdered ingredients in-house to improve shelf life, packaging, and transport efficiency. However, producing stable, functional powders from oil-based extracts via spray drying presents a key technical challenge. The ingredients must be encapsulated to protect them from thermal and environmental damage while preserving critical properties such as flavour release, flowability, and solubility.

Solution To address this, Baker & Co is collaborating with researchers at UNSW Sydney through an industry PhD project focused on developing advanced spray drying formulations. The project involves designing encapsulation systems that can effectively stabilise oil-based extracts during the drying process and maintain their performance in end-use food applications. The research will explore a range of encapsulating materials and processing conditions to identify optimal formulations that deliver the desired functionality, protection, and sensory characteristics.

Impact The outcomes of this project will enable Baker & Co to expand its product portfolio by introducing spray-dried flavour ingredients that are easier to store, transport, and apply in a wide range of food products. This capability not only reduces reliance on external manufacturers but also enhances the company’s competitiveness in the export market. By innovating with natural, shelf-stable powder formats, Baker & Co is positioned to strengthen its brand as a leader in sustainable, high-performance flavour solutions.