He’s developed lotions and potions for Procter & Gamble, protective coatings for premature babies and pest-thwarting films for plants. Spanning industry and academia, across disciplines, states and continents, UNSW Associate Professor Pat Spicer’s broad-ranging career has had one unifying flow: that of complex fluids, particularly nanomaterials. His latest challenge? Working with Sanitarium on a CRC project to make ‘stretchier’, foamier plant-based milks.

From Delaware oceanfront to industrial Ohio

Growing up on the US north-east coast, Pat Spicer hung out with oceanographers over summer while studying for a Chemical Engineering degree at the University of Delaware.

“I learned to do science in oceanography labs and fell in love with research there, and at the same time was being trained… to go into industry and do great practical things,” he says.

“And so where I am today really comes from a hybrid of being very interested in science and scientific research but also in its practical application.”

From Delaware, Spicer moved to Ohio, completing his PhD in Chemical Engineering with the Particle Technology Group at the University of Cincinnati. His thesis was on the design and synthesis of colloidal and nanoparticle materials.

Immediately after completing his doctoral studies, Spicer was snapped up by the Corporate Engineering Division of Cincinnati-based industrial materials giant Procter & Gamble group, working to scale up and manufacture complex fluid products across the firm’s various product divisions. In 2006, while still at UoC, Spicer formed P&G’s Microfluidics and Structured Fluids group, working to scale up and manufacture complex fluid products across the firm’s various product divisions.

It was the start of a fruitful 15-year association in which Spicer developed processes for novel

products and technology across all of P&G’s billion-dollar brands.

As a group leader within the company’s Central Engineering Research Department, he was responsible for several successful new products, manufacturing processes and patents, including P&G’s recently-patented ‘responsive droplet’ technology.

“At Procter & Gamble, I learned all about the types of products they make. And what I do now, which is around studying complex fluids and their flow, and how to design those properties and get them to interact with the human body or inorganic substrates, really came out of this background, of both science engineering research and applied uses of some of that research,” he says.

It was here, too, that Spicer achieved what he views as the highlight of his commercial career: co-inventing P&G’s US$30 million ‘cubosome’ patent portfolio.

Children’s Hospital Cincinnati used this novel, breathable material to develop the first-ever ‘artificial vernix’ – a protective, semi-permeable product that acts like a second skin, helping to prevent life-threatening infections in premature infants.

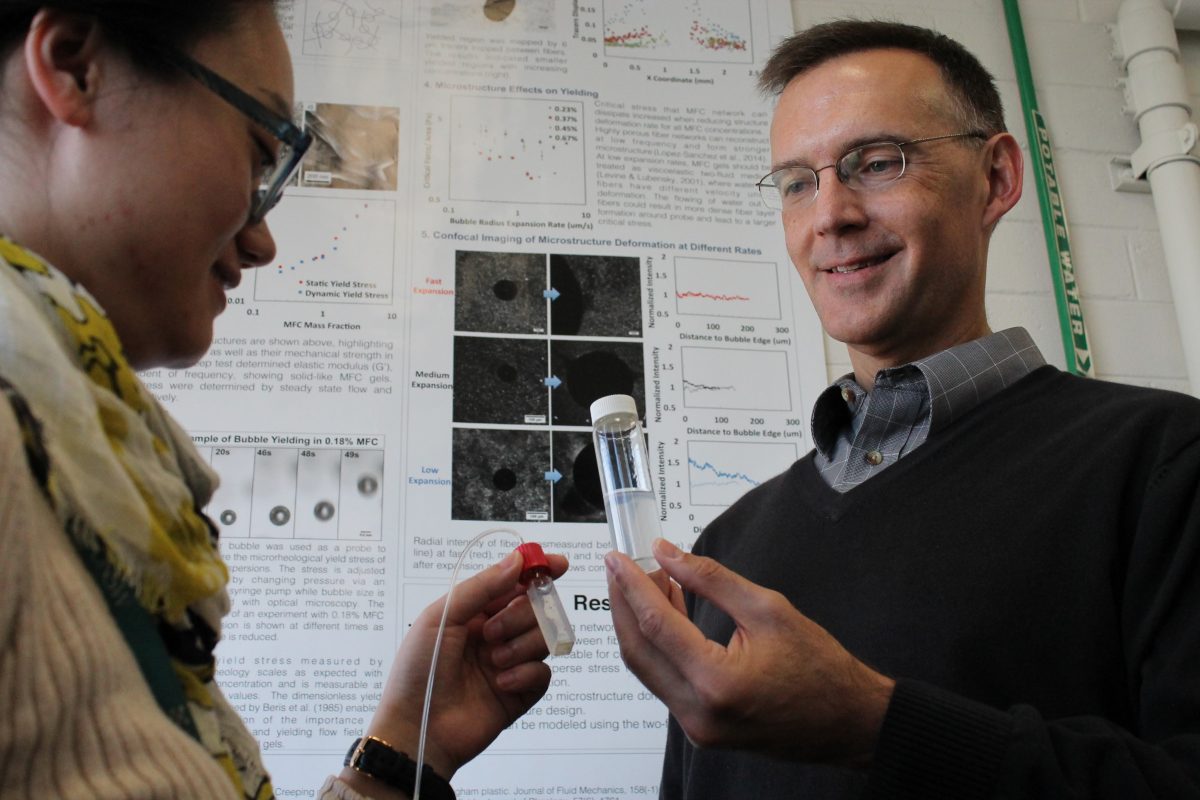

Dr Pat Spicer worked with major US-based manufacturer Procter & Gamble in the process and product development for 15 years before making the switch to academia. Credit: Patrick Spicer.

Changing continents

In 2012, Pat Spicer swapped his high-flying corporate career for a more low-key role in academia. At the same time, he made a life-changing sea-change from Cincinnati to Sydney, on Australia’s eastern seaboard.

At UNSW, as an Associate Professor in the School of Chemical Engineering, Spicer teaches three courses closer to his core interests. Two are courses in new product development; the third covers two of his favourite research areas: complex fluid microstructure and rheology.

Rheology, the study of the deformation and flow of materials, principally liquids and ‘soft solids’ such as plastics, is a field that holds a particular fascination.

“My work has always been centred around the flow and structure of soft and squishy materials,” he says. “Systems that are actually liquids but can physically behave as solids or liquids, depending on minor changes.”

Nano particles are also a recurrent research focus.

“About 10 years into my career, there was a realisation … that particles, and small particles, always factored into whatever I was doing,” Assoc. Prof. Spicer recalls.

“When I worked with chemical oceanographers … the group I was with was looking specifically at phytoplankton. And throughout my research, microparticles, nanoparticles, biological particles [were always part of] the work I was doing, floating around somewhere, attracting me like magnets.”

As an Associate Professor in UNSW’s School of Chemical Engineering, Pat Spicer teaches three courses: two in new product development; and one combining two of his research passions, complex fluid microstructures and rheology. Credit: Dr Robert Chan

Complex fluids with commercial applications

At UNSW, much of Assoc. Prof. Spicer’s research is around designing and developing novel microstructured fluid materials for various applications; scaling up soft-matter manufacturing processes; and evolving our understanding of the kinetic behaviour of fluids, the effects of particle shape on materials performance, and the way soft matter interacts with biological systems.

As leader, with colleague Assoc. Prof. Stuart Prescott, of the School of Chemical Engineering’s Complex Fluids group, he helms a tea working alongside industry to design ‘smart fluids’ with unique response and flow behaviour, linked directly to product and material performance.

Their lab has broad microscopy, microfluidic and rheology capability that Spicer, Prescott and the Complex Fluids group deploy to explore the behaviour of fluid coatings, films and other complex products. “We use advanced imaging and rheology techniques to understand fundamental complex-fluid properties – specifically, shape, structure and flow,” he explains.

“Simply put, we work with industry and academic partners to design fluid flow behaviour and performance. Most of our work deals with complex fluids – fluids containing small amounts of colloids, polymers, and surfactants that exhibit highly non-ideal behaviour with fascinating dynamics.

“Complex fluids are a key part of most major products and manufacturing processes. Our experiments try to link fluid structure and flow to improve our physical modelling capabilities in this area.”

New formulations, nanomaterials and novel-shaped emulsions, microfluids and 3D printed materials

Assoc. Prof. Spicer has also co-invented nanomaterials and novel-shaped emulsions for use in everything from pesticides to foods to vaccines.

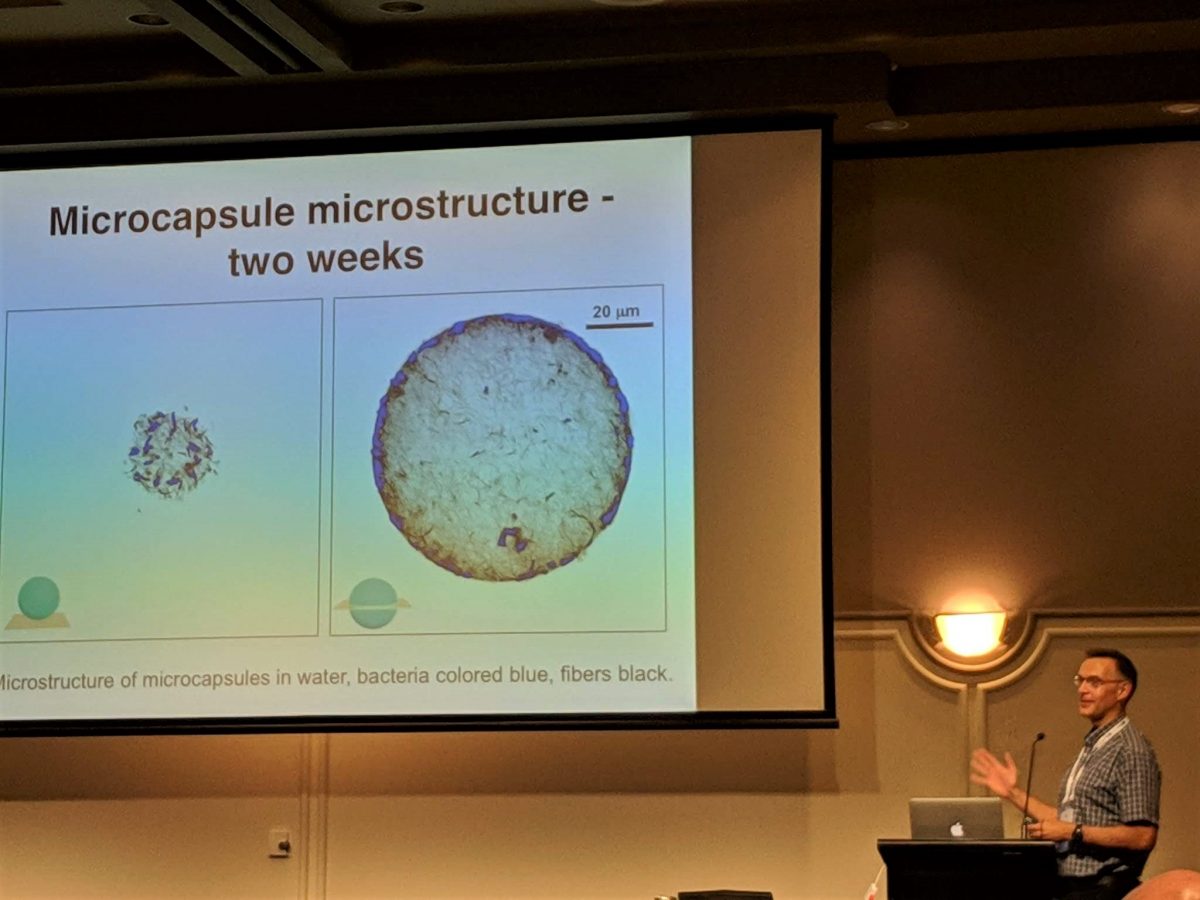

He’s helped to develop ‘engineered nanocellulose’, harnessing bacterial producers of cellulose nanofibres to weave, template and manufacture advanced materials. He’s also created cubosome and hexosome nanoparticles – nanostructured liquid crystal particles with unique shapes and biological functions.

By dispersing one liquid, such as an oil, in another, such as water, he’s come up with novel-shaped emulsion droplets for use in foods, pesticides, cosmetics and vaccines.

His research also ventures into the futuristic terrain of innovative microstructured fluid products with biological and industrial applications: microrheology, microfluids, new formulations and sophisticated 3D-printed materials.

Assoc Prof Patrick Spicer gives a lecture on bacterially-produced nanocellulose capsules. Credit: Dr Haiqiao Wang

ARC project grants: stretchy liquids, Smartdrops, clingy sprays and exploring the causes and effects of ‘thunderstorm asthma’

Over the past decade, Assoc. Prof. Spicer has been the recipient of a string of prestigious Australian Research Council (ARC) grants.

He was awarded an ARC LIEF Project grant to construct sophisticated rheoscattering facilities at ANSTO’s Lucas Heights and Clayton campuses. These facilities will enable Spicer and fellow researcher to study high-speed, stretching and other complex flows, as well as matching applied processes.

A recent ARC Discovery Project saw Assoc. Prof. Spicer teasing out cause and effect in the much-publicised phenomenon of ‘thunderstorm asthma’, exploring new mechanisms of particle formation in thunderstorms’. As part of that project, he and his research team performed the first studies of ‘pollen rupture’ behaviour in extreme conditions.

“I’m looking forward to some fascinating experimental results on the release of biological nanoparticles from pollen grains so we can better understand the causes of catastrophic thunderstorm asthma,” he says.

An earlier ARC Discovery Project grant funded him to develop, engineer and test novel, high-performance sprays with unique ‘cling’ to coat leaves, thereby protecting them from attack by harmful plants and insects.

Yet another underwrote his research into the development of ‘Smartdrops’: novel-shaped aerosol particles that enhance drug delivery significantly.

Pat Spicer in the office. Credit: Adelaide Spicer

Research with real-world applications – and broader benefits

After a decade and a half working for a global corporation, Assoc. Prof. Spicer is no stranger to commercially driven collaborations. The bulk of his research, in the US and Australia, has been geared towards real-world applications.

That doesn’t mean it’s all about the profits. Much of Spicer’s research has helped alleviate suffering and redress environmental harm – whether that be inventing a new way to help premature babies survive, deliver vaccines, alleviate ‘thunderstorm asthma’, protect crops against pests – or ensure vegans and coeliacs can enjoy better plant-based cappuccinos and café lattes.

In Assoc. Prof. Spicer’s most recent research collaboration, with new CRC participant Sanitarium Health Food Group, he’s looking to optimise key functional properties of its Barista plant-based milks.

Getting a mix of oats or almonds and water, free of fats, emulsifiers and synthetic-stabilisers to mimic the creaminess and ‘stretchiness’ of dairy milk is no simple matter.

But Pat Spicer’s up for the challenge, keen to use his expertise in manipulating complex fluids to help move the world towards healthier, more sustainable ways of living.

Collaboration: crucial to solving ‘the big challenges’

More broadly, Assoc. Prof. Spicer contends, collaboration – between academia and industry, and across research institutions and areas – is the best and sometimes, the only way to solve the complex challenges of the 21st century.

“Over my career, I’ve worked with oceanographers, food scientists, the chemical industry, hospitals, neonatal specialists, meteorologists, physicists – collaboration is central to the work I do,” he says.

“In industry, one of my jobs was to work with academics and feed ideas, and fund research but also just collaborate, and act as a bridge for the work that was going on.

“Collaboration is crucial if we’re to solve the major problems currently facing humanity. The more we can truly bridge interdisciplinary gaps, the faster we can make real progress on big questions.

“Some of the most interesting and rapid progress has been made when diverse specialties collaborate.”

More information about Assoc Prof. Pat Spicer

- UNSW academic profile

- ResearchGate profile

- Google Scholar profile

- Select publications

- Profile on the Cluster for Advanced Macromolecular Design (CAMD) website.

Fields of research

- Soft Condensed Matter

- Rheology

- Colloid and Surface Chemistry

- Powder and Particle Technology

- Food Chemistry and Molecular Gastronomy (excl. Wine)

- Crop and Pasture Protection (Pests, Diseases and Weeds)

- Pharmaceutical Sciences