Case study

Developing a smart robotic mobile platform to transform indoor pollination operations

The industry challenge

Horticulture is one of Australia’s most labour intensive agricultural sectors. Labour accounts for a significant portion of crop production costs, particularly in tasks such as monitoring, harvesting and pollination. This is particularly true for indoor growers, who often must resort to manual pollination due to the low numbers of natural pollinators in Australia.

The strategic solution

In response to this pressing issue, Future Food Systems (FFS) played a pivotal role in facilitating a solution. FFS effectively connected P’Petual Holdings, a commercial greenhouse operator, with the Robotics team at Queensland University of Technology (QUT). This collaboration resulted in the development of an innovative, fully automated mobile system for pollination. Under the guidance of Dr Chris Lehnert and his expert team at QUT, a solution was developed that not only addressed P’Petual’s needs but has the potential to transform the entire indoor horticulture sector.

The impact

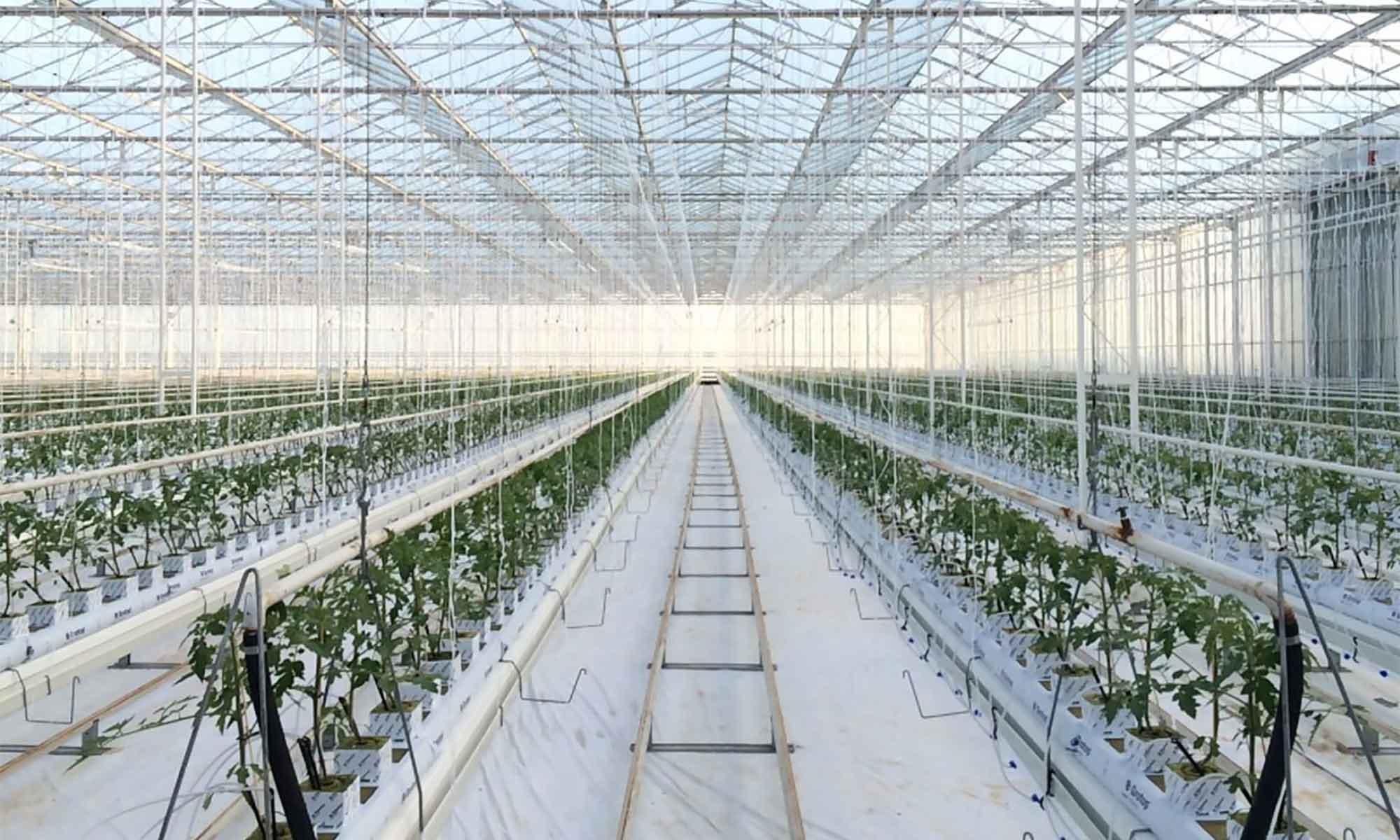

By the conclusion of FY2022/23, the fully automated pollination system had been seamlessly integrated into P’Petual’s commercial glasshouse facility. This reduces the necessity for human intervention, resulting in substantial time and cost savings. The system exhibited remarkable efficiency, consumed minimal energy and boasted the flexibility to recharge during offpeak hours or with renewable energy sources. P’Petual, spurred by this success, utilised the proceeds from selling the intellectual property of its robotic pollination system to accelerate its business expansion. The timely co-funding and efficient project approval processes facilitated by FFS played a pivotal role in expediting the development of this groundbreaking solution. Furthermore, the partnership with FFS and QUT provided P’Petual with access to cuttingedge research and highly skilled personnel, accelerating the company’s progress.

What's next?

The resulting automated mobile greenhouse pollination system not only met immediate needs but opened doors to a wide array of applications within indoor horticulture and beyond. Dr Lehnert’s vision involves adapting the platform to support various labour-saving robotic equipment, potentially revolutionising tasks such as monitoring, counting, harvesting and pest detection in the agricultural sector. Encouragingly, two potential commercial partners have expressed keen interest in collaborating to commercialise this transformative robotic platform. Furthermore, the dissemination of the project’s findings through an upcoming academic paper by Dr Lehnert and Dr John Skinner promises to contribute significantly to the field of agricultural robotics.