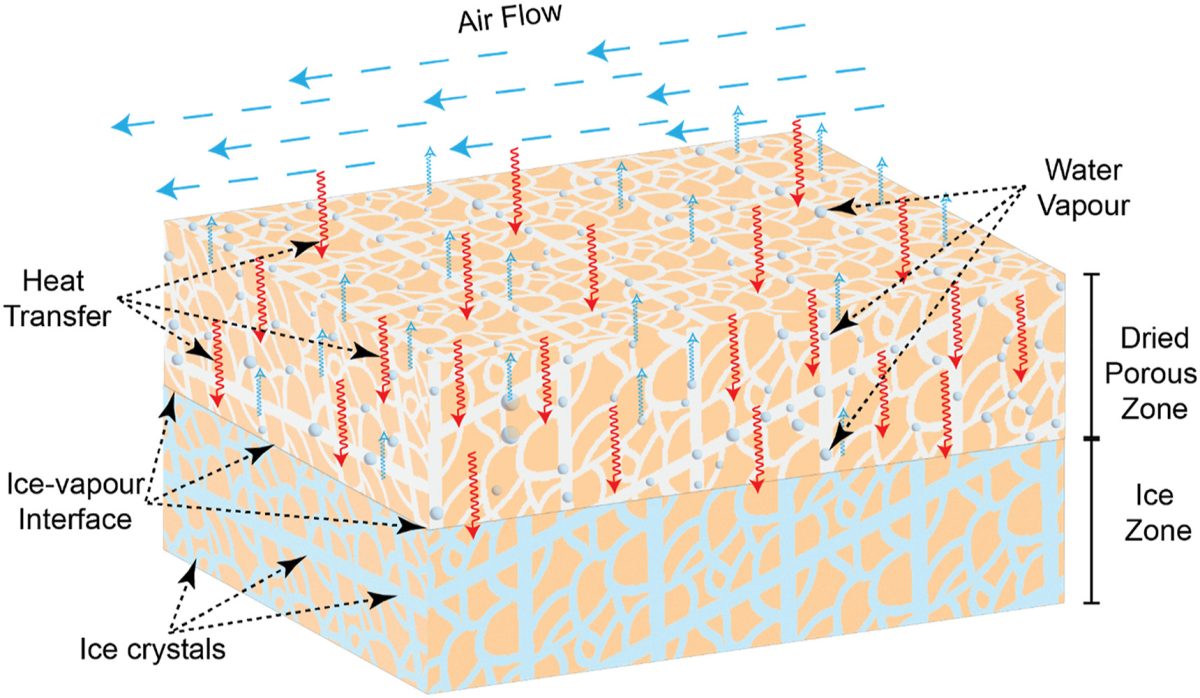

Challenge Vacuum freeze-drying is widely used for preserving food products due to its ability to retain quality and nutritional value. However, it remains limited by high operational costs and extended drying times, which hinder its broader industrial adoption. There is a growing need for more efficient and cost-effective alternatives that maintain the advantages of freeze-drying while improving throughput and energy efficiency.

Solution This research project explores the application of direct ultrasound in Atmospheric Freeze Drying (AFD) to enhance water diffusivity and reduce drying time. By integrating ultrasound technology into the AFD process, the aim is to accelerate moisture migration and improve overall drying efficiency. The project involves both computational modelling and the design and fabrication of a prototype ultrasound-assisted AFD system. The system’s performance will be evaluated by analysing the drying kinetics and conducting physical and chemical characterisation of model foods.

Impact If successful, the ultrasound-assisted AFD system could offer a viable, lower-cost alternative to traditional vacuum freeze-drying, significantly improving processing efficiency. This innovation holds the potential to reduce energy use, increase productivity, and maintain high product quality which will benefit the food industry by enabling more sustainable and scalable drying solutions. The outcomes may pave the way for broader adoption of AFD technologies across a range of food applications.