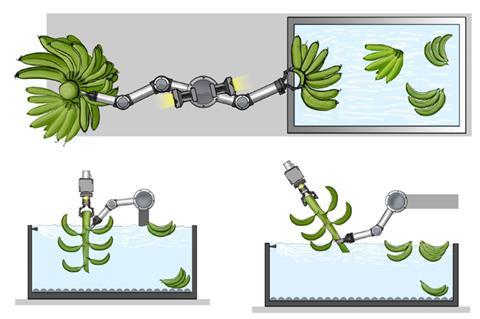

Challenge Banana de-handing is a core process at all banana processing facilities. It is a repetitive and physically demanding activity that if automated, could improve processing efficiencies and provide a valuable integration point for robotics systems. Research is pertinent given current workforce reliability and supply chain issues, TR4 disease, and low-cost imports threats.

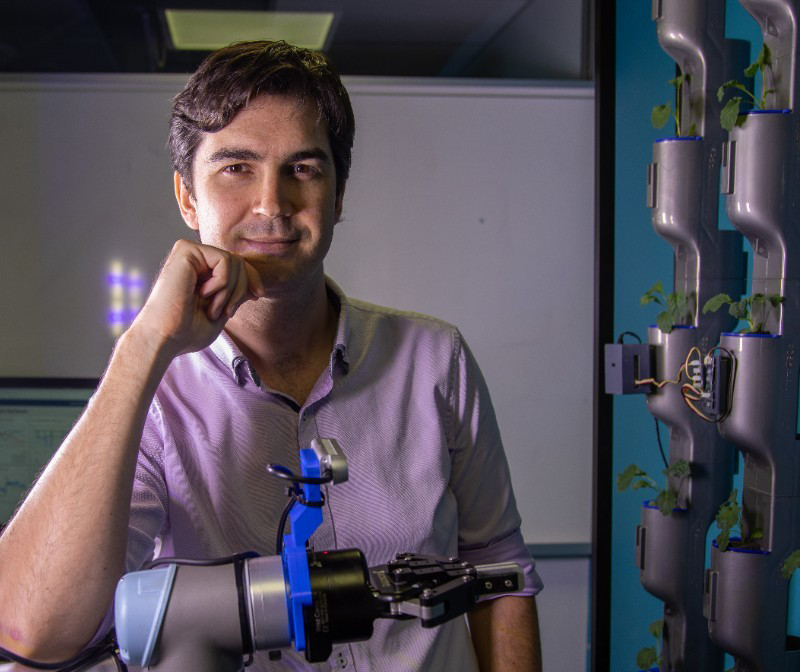

Solution This research focuses on the automation of banana de-handing, aiming to reduce manual labour and enhance processing efficiency. By developing and integrating robotic systems into this core process, the project addresses labour constraints and creates opportunities for wider automation adoption in banana handling and packaging operations.

Impact Automating de-handing will boost operational efficiency, improve workplace safety, and reduce dependence on inconsistent labour supply. It also provides a critical entry point for robotics in horticulture, supporting the Australian banana industry’s resilience and competitiveness in the face of mounting biosecurity and market challenges.