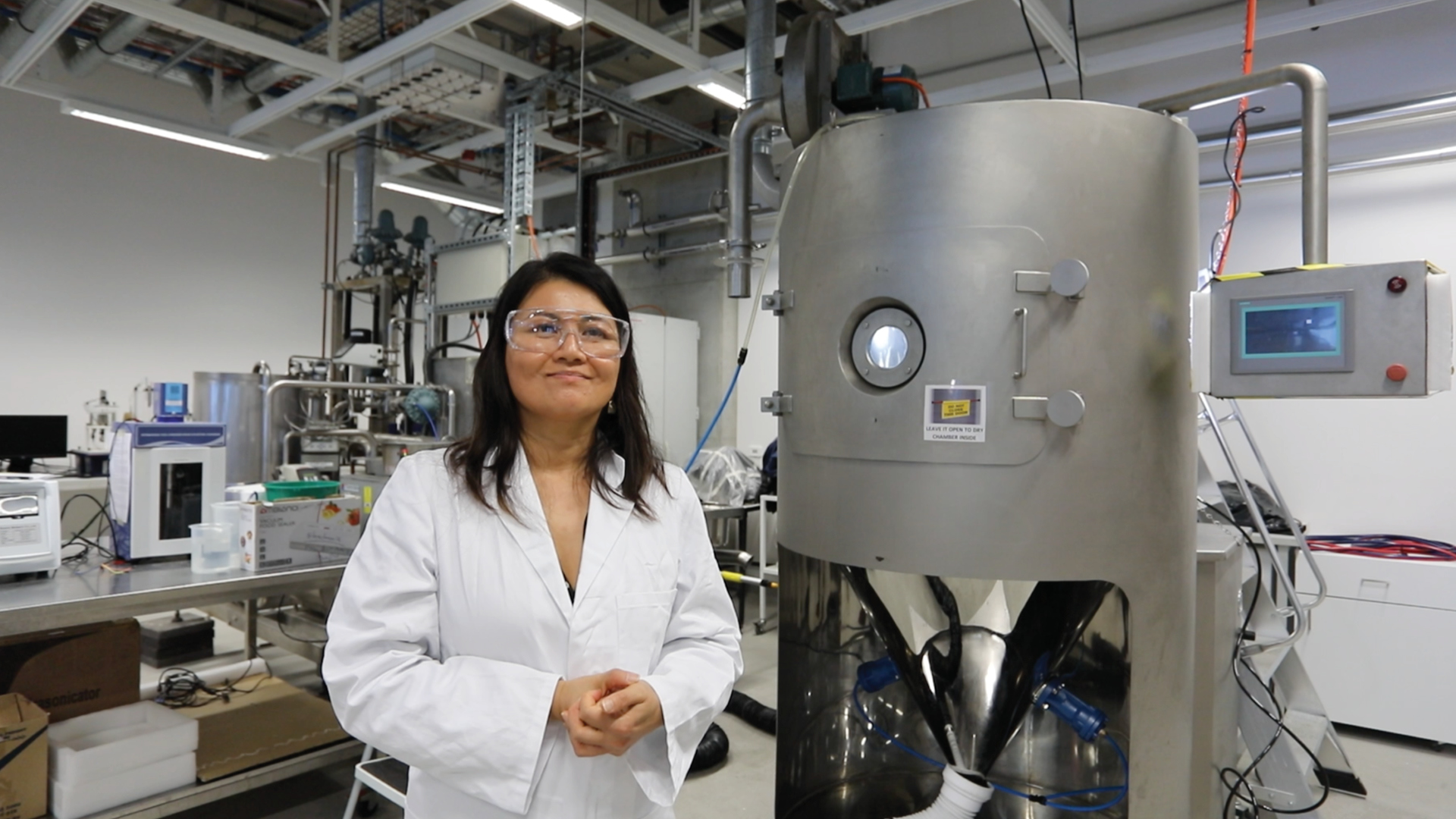

EcoMag, founded by Dr Tam Tran and Tony Crimmins, set out to revolutionise the upcycling of magnesium-rich waste from sea-salt processing in Western Australia. Although Dr Tran had developed a proprietary method for converting this waste into magnesium hydrocarbonate, scaling and refining the process remained a major hurdle. Traditional ‘wet chemistry’ methods were labour-intensive and inefficient, creating a need for a more scalable, cost-effective, and sustainable production approach.